PWM Input Capture handling. More...

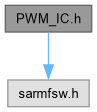

#include "sarmfsw.h"

Data Structures | |

| struct | PWM_IC |

| PWM input capture structure. More... | |

Typedefs | |

| typedef struct PWM_IC | PWM_IC |

Functions | |

| GPIO_PinState | PWM_IC_get_Pin_State_Callback (const uint8_t idx) |

| PWM Input Capture get Pin state (in case of timeout, or at startup) | |

| FctERR | init_PWM_IC (PWM_IC *const pPWM_IC, TIM_HandleTypeDef *const pTim, const uint32_t Direct_Channel, const uint32_t Indirect_Channel, const uint32_t Scale) |

| Init PWM Input Capture channel. | |

| uint32_t | get_PWM_IC_Freq (PWM_IC *const pPWM_IC) |

| Get current PWM Input Capture frequency. | |

| uint32_t | get_PWM_IC_DutyCycle (PWM_IC *const pPWM_IC) |

| Get current PWM Input Capture duty cycle. | |

| void | PWM_IC_handler (void) |

| PWM Input Capture handler. | |

Variables | |

| PWM_IC | PWMin [1] |

Detailed Description

PWM Input Capture handling.

- Copyright

- MIT (c) 2017-2024, SMFSW

PWM_In configuration: TIM with multiple channels with slave mode capability shall be used

Slave Mode: Reset Mode Trigger: TI1FP1/TI2FP2 (depending physical MCU pin used tied to channel 1 or 2) Channel tied to pin: Input Capture direct mode Channel (2nd one): Input Capture indirect mode

Prescaler & CLK div: 0, No CLK div Counter Period: max possible value Counter Mode: Up Auto-Reload Preload: Disabled Trigger Output parameters: Disabled Input Capture Channel tied to pin: Rising Edge, Direct, No CLK div Input Capture Channel (2nd one): Falling Edge, Indirect, No CLK div

Instead, CubeMX Combined channels capture may be configured to PWM input capture, avoiding manual timer configuration

GPIO configuration: Alternate Function Push Pull ; Pull Up (if needed) ; High Speed may be recommended

NVIC configuration: Enable interrupt(s) if PWM_IC_NO_IT is not defined at project level

- Note

- Define NB_PWM_IC symbol with number of inputs at project level to use PWM_IC functionalities

- Define PWM_IC_NO_IT symbol at project level to disable TIM interrupts driven capture

- Warning

- Input Capture limitation:

- Lower/Higher frequency/duty cycle measurable totally depends on TIM configuration and clocks used.

- Continuous signal (pin held low or high) is detected automatically after timeout:

- automatically when using interrupts driven PWM input capture

- by calling PWM_IC_get_Pin_State_Callback without interrupts

- !!Please note there can be up to 1 second with startup timeout during which low to high continuous signal may be misinterpreted before retrieving values!!

- If PWM signal to capture can never become continuous, it may save some time of servicing interrupts to disable them (with PWM_IC_NO_IT symbol)

Typedef Documentation

◆ PWM_IC

| typedef struct PWM_IC PWM_IC |

Function Documentation

◆ get_PWM_IC_DutyCycle()

| uint32_t get_PWM_IC_DutyCycle | ( | PWM_IC *const | pPWM_IC | ) |

Get current PWM Input Capture duty cycle.

- Parameters

-

[in] pPWM_IC - pointer to PWM_IC instance

- Returns

- Measured duty cycle

◆ get_PWM_IC_Freq()

| uint32_t get_PWM_IC_Freq | ( | PWM_IC *const | pPWM_IC | ) |

Get current PWM Input Capture frequency.

- Parameters

-

[in] pPWM_IC - pointer to PWM_IC instance

- Returns

- Measured frequency

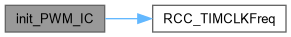

◆ init_PWM_IC()

| FctERR init_PWM_IC | ( | PWM_IC *const | pPWM_IC, |

| TIM_HandleTypeDef *const | pTim, | ||

| const uint32_t | Direct_Channel, | ||

| const uint32_t | Indirect_Channel, | ||

| const uint32_t | Scale ) |

Init PWM Input Capture channel.

- Parameters

-

[in,out] pPWM_IC - pointer to PWM input capture instance [in,out] pTim - pointer to TIM instance [in] Direct_Channel - Direct Channel used for PWM input capture [in] Indirect_Channel - Indirect Channel used for PWM input capture [in] Scale - PWM input capture duty cycle output scale

- Returns

- FctERR - Error code

◆ PWM_IC_get_Pin_State_Callback()

| GPIO_PinState PWM_IC_get_Pin_State_Callback | ( | const uint8_t | idx | ) |

PWM Input Capture get Pin state (in case of timeout, or at startup)

- Weak Functions

- Function declared as weak, needs to be customly implemented in user code, otherwise returns RESET state

- Parameters

-

[in] idx - PWM_IC instance index

- Returns

- Pin state

◆ PWM_IC_handler()

| void PWM_IC_handler | ( | void | ) |

PWM Input Capture handler.

- Note

- Shall to be called periodically if PWM_IC_NO_IT is defined

- When interrupts are used, handler can be called periodically (but not required), results getters will perform the conversion when required

Variable Documentation

◆ PWMin

|

extern |

Generated by